Execution of the Strategy in 2022

JSW S.A. runs a continuous process of business optimization and efficiency improvement in the key areas of its business. These activities are adapted on an ongoing basis to the changing environment and have different magnitudes depending on the current phase in the Company’s business cycle. They are aimed not only at improving performance indicators but also at preparing the Company for downturns

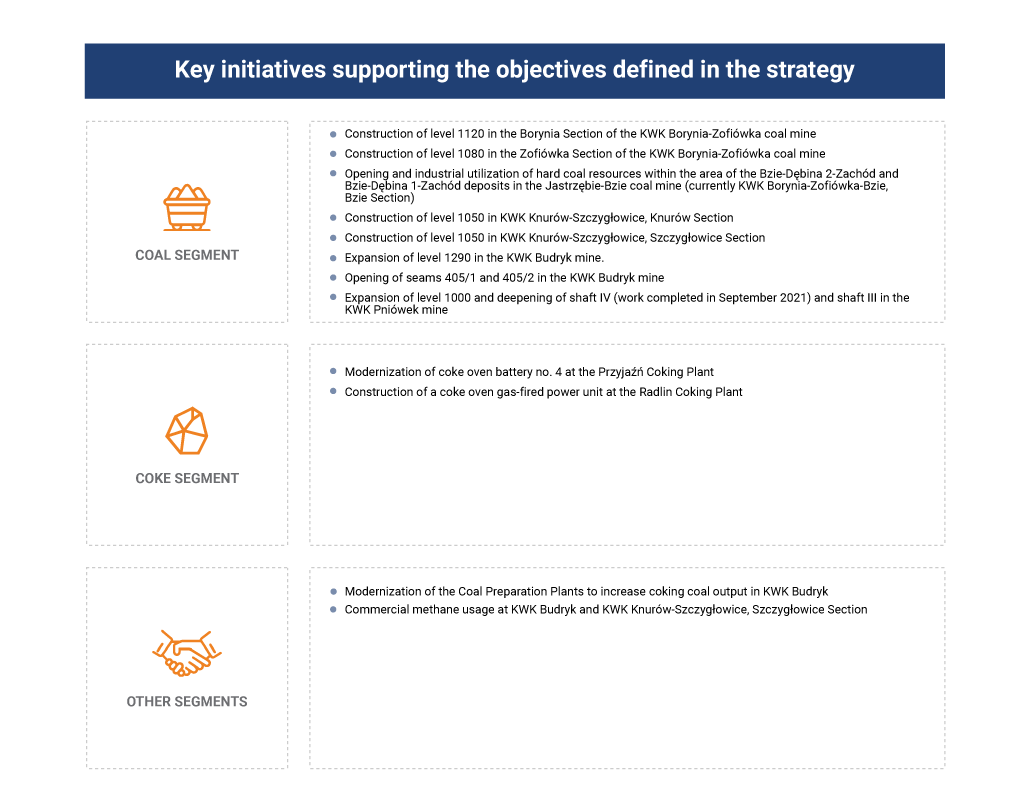

KEY INITIATIVES SUPPORTING THE OBJECTIVES DEFINED IN THE STRATEGY

DEVELOPMENT OF BZIE-DĘBINA 2-ZACHÓD AND BZIE-DĘBINA 1-ZACHÓD DEPOSITS

The objective of the investment is to secure access to resources of coking coal of quality desired by the market. The estimated recoverable coal reserves in the Bzie-Dębina 2-Zachód and Bzie-Dębina 1-Zachód up to a depth of 1,300 m are roughly 181.0 million tons. In the first half of 2022, the N-2 longwall in seam 505/1 was exploited in the “Bzie-Dębina 2-Zachód” mining area. The works were completed in October 2022. As a result of an analysis of various scenarios of operation of this areas and having developed the optimum model for its production capacity, it was decided that the works designed in the “Bzie-Dębina 2-Zachód” and “Bzie-Dębina 1-Zachód” deposits should be part of the mine of the neighboring KWK Borynia-Zofiówka colliery as a separate Section. As of 1 January 2023, a three-section mine named KWK Borynia-Zofiówka-Bzie was established. At the same time, documentation is being prepared (new Environmental Impact Reports are being consulted with the Regional Environmental Protection Directorate) to change to the concession (expansion of the mine site) for the Bzie-Dębina 2-Zachód” deposit and to fully utilize the concession for the “Bzie-Dębina 1-Zachód” deposit.

MODERNIZATION OF COKING BATTERY 4 IN THE PRZYJAŹŃ COKING PLANT

The new Battery No. 4 will bring real environmental benefits in the form of reduced air emissions, thanks to the implementation of a number of modern technical and technological solutions.

The modernization is combined with a change in the technology of charging the coke oven chambers from the top charging to the stamp charging system, which makes it possible to reduce the use of type 35 coal in favor of type 34 (semi-soft coking) coal, and consequently to achieve an economic effect - and, in conjunction with the Coke Dry Quenching Plant, to maintain high quality parameters of the coke.

The implementation of the new technology would require reconstruction of the facilities for the preparation of coal and the collection of coke, collection of coke oven gas, power supply and electrical installations will have to be modified and expanded and a number of infrastructural facilities related to the entire coke production department and auxiliary management. The use of a stamp charging system in combination with a coke dry quenching plant (CDQ) is an effective and innovative solution on a European scale.

CONSTRUCTION OF A POWER UNIT IN THE RADLIN COKING PLANT

With respect to the investment projects associated with construction of the power unit in the Radlin Coking Plant using the coke oven gas (generated during coke production) for generation of electricity and heat, works were continued connected with the construction of a 28 MWe and 37 MWt power unit using cogeneration. Advanced execution and assembly works in the areas of individual installations and technological equipment are conducted. The General Contractor for the Investment (Rafako S.A.) carried out works in the following areas: power building with the block control room, engine room building, boiler house building, cooling water pumping station building, water treatment station, fan cooler, gas flare, water and sewage networks, short circuit chokes building, DEMI water tank, fire water pumping station, fuel oil tank and gas path. As part of the construction of the Flue Gas Desulfurization Plant, the construction of foundations for flue gas fans was continued.

Steam boilers that are part of the Radlin CHP Plant have passed the pressure test. A completed water test, confirmed by a third-party oversight body, is one of the most important stages of the project.

MODERNIZING THE COAL PREPARATION PLANTS

Tasks related to the modernization of the Coal Preparation Plants in the Knurów Section and Szczygłowice Section were completed in 2022. A project to modernize the Coal Preparation Plant in KWK Budryk is underway. Completed and ongoing activities are expected to generate an increase in coking coal yield. The project will result in the development, modernization, and appropriate equipment of the Coal Preparation Plants which are expected to bring about:

- increasing the output of type 34 and 35 coking coal in KWK Budryk,

- increasing the share of coking coal production in JSW S.A., ultimately above 90% from 2026.

In 2022, the Contractors continued to complete the works related to the expansion and modernization of the Coal Preparation Plant at JSW S.A. KWK Budryk broken down into individual tasks.

ENERGY ACTIVITY

- 136 MWe of installed generation capacities in the Group

- 26 MWe of installed generation capacities in the JSW Group’s mines

One of the JSW Group’s strategic objectives is to strive to balance the consumption and auto-production of electricity. In addition to the status of an electricity offtaker, the Group has a concession for generation, trading, and distribution of energy (JSW KOKS). One of the Group’s strategic objectives is to strive to balance the consumption and auto-production of electricity.

As part of the program entitled “Commercial Methane Utilization” (GWM), investment projects were run in KWK Budryk and KWK Knurów-Szczygłowice in 2022, involving the construction of cogeneration units powered by methane from the methane drainage of mines. At present, the Methane Emissions Reduction Program, being a continuation of the GWM Program, is operational.

The project involving the construction of the Radlin CHP Plant with a capacity of 28 MWe using coke oven gas to generate heat and electricity is under way. This task is critical to the JSW Group as it supports the utilization of 100% of the coke oven gas surplus by consuming it as a fuel for combustion in the cogeneration unit. Currently, the JSW Group’s installed generation capacity is approx. 136 MWe, including approx. 26 MWe in JSW S.A. mines.

Additionally, measures for further optimizing electricity consumption and enhancing energy efficiency, the development of own RES capacity and ratcheting up the share of “green energy” have been planned. The key element of the Strategy consists in the construction of large-scale photovoltaic installations on land owned by the Group companies.

The key element of the Strategy consists in the construction of large-scale photovoltaic installations on land owned by the JSW Group’s business units. So far, plots of land and built features with a potential for RES power plant construction have been designated and conceptual designs will be prepared for them.

Read more here about energy consumption.

COMMERCIAL METHANE UTILIZATION

The execution of the program entitled “Commercial Methane Utilization” involves the extension of infrastructure to generate electricity and heat by using all of the captured methane. Methane originating from coal deposits will be converted into electricity and used for the mines’ own needs.

Currently, JSW has built electrical capacity related to methane utilization of approximately 26 MWe.

From the beginning of 2022 to the end of Q4 2022, the methane emissions into the atmosphere were reduced by approx. 91 million m3, of which by approx. 23.5 million m3 in Q4 2022 alone. In 2022, 168 thousand MWh of electricity was produced from methane (of which 98 thousand MWh was own energy production, the remaining volume represented purchases of energy generated from methane sold). In Q4 2022, in turn, the volume was 42 thousand MWh, of which 20 thousand MWh accounted for by auto-production.

Read more here about the measures taken in the field of methane utilization.