Concern for climate

Keeping in mind the nature of JSW Group's activities, undertaking activities related to respecting non-renewable natural resources is exceptionally important due to their scarcity. This entails their efficient acquisition, processing and use at each stage of the economic value creation process.

The Group exercises continuous oversight and monitoring as well as focuses on maximally reducing the scale of pollution reaching the environment and takes steps essential to optimally manage natural environment areas and resources.

Operating in the extractive industry also entails a large indirect impact on the use of natural resources, generation of waste, consumption of energy and fuels and emissions into the air. Coal mining is inextricably accompanied by methane as an associated mineral that constitutes a greenhouse gas which impacts our climate. Methane emissions constitute approx. 71% of JSW Group's total greenhouse gas emissions, expressed in CO2 equivalent.

JSW strives to maximise its capture and use but due to miner safety concerns it is not possible to avoid it being emitted along with ventilation air from exhaust shafts.

JSW Group has direct and indirect impact on climate changes:

- DIRECT IMPACT on climate change results from its mining and production operations that generate methane emissions in the case of coal mining and CO2 in the case of coke production and energy generation

- INDIRECT IMPACT on climate change is mainly related to the processes of transporting commodities, materials and products, the energy-intensity of the production process and the management of extractive waste

Impact of climate change on JSW Group

Climate changes may have an impact on the Group's activities in the form of adverse, variable weather conditions that can cause disruptions in mining, production and product deliveries to customers and in supplying essential production materials to the Group's facilities.

Drought can have a particular impact by preventing water abstraction for production purposes and discharging salted mining water to surface waters. Higher temperatures in the summer may also have an impact on ventilation and air-conditions systems in mining excavations. Coking plants, as continuous-operation facilities in which pausing the production process would result in damages, are particularly exposed to weather changes.

The current policy for transitioning to a low-emission economy and the European Green Deal objectives for reaching climate neutrality by 2050 may lead to a reduction in fossil fuel mining and use. In connection with this, legislative and regulatory initiatives at domestic and EU level can have a material impact on JSW Group.

Actions for climate

In cooperation with scientific institutes, JSW has begun developing a road map for the impact of climate change on JSW Group's business, strategy, investment decisions, assets, productivity, market and the society. JSW has outlined general directions for activities intended to counteract climate changes:

Estimating, monitoring and balancing the carbon footprint of the organisation and its products - coal and coke

Carbon footprint

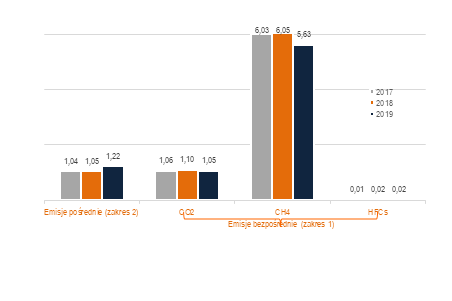

In 2019, JSW Group continued estimating the carbon footprint for the entire organisation (JSW Group) and for the major coal and coke production processes with the use of an IT tool for such calculations. These calculations take into account the emissions of the following greenhouse gases: CO2, methane and hydrofluorocarbons (HFCs). The calculations are prepared in compliance with the GHG Protocol - corporate standard and GHG Protocol - product standard, based on indicators published in the IPCC Fifth Assessment Report in 2014. JSW Group selected the operational control approach to define the organisation boundaries for the purpose of inventorying greenhouse gas emissions. JSW's Management Board decided to publish the organisation's carbon footprint. The carbon footprint of coal and coke products will be made available at the explicit request of JSW Group's counterparties for these products.

Scope 1 includes direct emissions from sources located at all of the Group's companies, including the following emissions:

- from the combustion of fuels in stationary sources,

- from technological processes, including emissions from coking, emissions related to ventilation, emissions from cooling, emissions from other processes (e.g. welding),

- from the combustion of fuel in combustion engines.

Scope 2 indirect emissions cover emissions related to the generation of: electric energy, thermal energy, cooling, compressed air, purchased and used by the Group's companies.

|

CARBON FOOTPRINT - ORGANISATION JSW GROUP |

DIRECT EMISSIONS (SCOPE 1) |

INDIRECT EMISSIONS (SCOPE 2) | TOTAL EMISSIONS (SCOPE 1+2) |

||||

|---|---|---|---|---|---|---|---|

|

EMISSIONS PER PRODUCT UNIT (COAL + COKE) |

EMISSIONS PER PLN 1 MILLION IN REVENUE | ||||||

| YEAR | million Mg CO2e | CO2 | CH4 | HFCs | million Mg/million Mg | million Mg/million PLN | |

| 2017 | 8.14 | 1.06 | 6.03 | 0.01 | 1.04 | 0.458 | 0.000917 |

| 2018 | 8.22 | 1.10 | 6.05 | 0.02 | 1.05 | 0.447 | 0.000838 |

| 2019 | 7.92 | 1.05 | 5.63 | 0.02 | 1.22 | 0.443 | 0.000914 |

Organisation boundaries - operational control approach - 100% of emissions from all JSW Group companies

Operational boundaries - direct and indirect emissions in scopes 1 and 2. Due to the fact that both coal and coke constitute indirect products in further processes, scope 3 in the organisation's carbon footprint was omitted.

In accordance with the methodology recommended by the GHG Protocol, the uncertainty of the organisation's carbon footprint is specified at 8%.

Emissions of other substances into the air

Other substances, emitted mainly as a result of: combustion of fuel in boilers, gas engines, combustion engines in surface and underground vehicles and equipment and machinery do not exceed the permitted values or benchmark values.

| EMISSIONS OF OTHER SUBSTANCES (JSW GROUP) (MG) | 2019 | 2018 | CHARGE 2018=100 |

|---|---|---|---|

| MASS OF OTHER SUBSTANCES EMITTED INTO THE AIR, INCLUDING: | 6,763.8 | 7,935.8 | 85.2 |

| SOx | 1,600.3 | 1,772.6 | 90.3 |

| NOx | 2,479.7 | 2,851.0 | 87.0 |

| CO | 2,312.1 | 2,870.5 | 80.5 |

| Total particulate matter | 371.7 | 441.7 | 84.2 |

| EMISSIONS OF OTHER SUBSTANCES PER UNIT OF REVENUE MG/PLNk | 0.78 | 0.81 | x |

Searching for technological, process and legal solutions that will support the battle against climate changer

Energy Cluster

The project aims to create a cluster that will include local government units in areas where JSW Group operates as well as institutions and businesses operating there that are invited to participate. Forming the Cluster will let JSW, as one of the largest players on the coking coal production market, get involved in activities that support local initiatives in environmental protection, energy efficiency, development of renewable energy sources and promoting the Company's existing activities in this field as part of the cluster.

The project aims to create a cluster that will include local government units in areas where JSW Group operates as well as institutions and businesses operating there that are invited to participate. Forming the Cluster will let JSW, as one of the largest players on the coking coal production market, get involved in activities that support local initiatives in environmental protection, energy efficiency, development of renewable energy sources and promoting the Company's existing activities in this field as part of the cluster.

The initiative is intended to improve local energy security by developing dispersed energy, including renewables, while maximising economic effectiveness. As part of this project being implemented by JSW Group, municipalities with identified potential for cooperation within an energy cluster were indicated. A range of meetings were held as part of cooperation with local authorities to discuss areas of potential cooperation and review energy assets. These meetings and analyses resulted in an initial outline of the Energy Cluster and constitute the basis for formulating the Energy Cluster's Strategy - a document defining the cluster's formal and legal activities and incorporating analyses that are essential for the proper and long-term operation of the Energy Cluster.

Effectively using natural resources

Launched at the Budryk mine in November 2019, Bolter Miner 12CM30 is the first such machine in Polish mining.

The Bolter Miner was purchased by JSW Innowacje, a JSW subsidiary, in 2018 as part of the project "Hydraulic bolting system." The Bolter Miner was produced in the U.S. and arrived in Poland at the beginning of August 2019. The machine was transported to Komatsu's Polish headquarters in Tychy. The machine was then assembled and all trial tests were performed. The crew that currently operates the machine received training back then. Next, the machine was again disassembled and transported to the Budryk mine, where it was sent underground. There, in a specially prepared assembly chamber the Bolter Miner was once again assembled and prepared for operations. Next, in November the Bolter Miner began cutting a roadway using a bolting system.

The Bolter Miner is exceptionally efficient. According to the manufacturer, the maximum haulage is 27 tonnes per minute, which reduces costs. Bolting systems are used all over the world, including in Australia, South Africa, Russia and Czech Republic. This technology is much cheaper than pillar systems and equally safe. The cost of preparatory works at JSW's mines constitutes a significant part of coal mining costs therefore the Company is searching for the most efficient solutions. Using a bolting system is intended to reduce the costs of preparing for coal extraction

Oprimising the energy intensity of operations by maximising self-generation of energy (use of methane and coke oven gas)

The rising share of self-generated energy not only means lower costs but is also a step toward shielding the business model from higher energy costs. Generating energy from previously unused own sources is an example of adapting to the consequences of changes related to climate policy.

JSW Group is taking steps to address the use of coke oven gas. Just several years ago, excess coke oven gas, which is a by-product of coke production that was not used in the coking battery itself, was treated as waste. Today, more and more installations use it to generate energy.

The entire volume of gas is economically used in modernised installations. Some of the gas, mostly in the winter, is sold to external customers (production of heat for heating purposes). These activities are supported by JSW KOKS's Energy Management System, deployed and certified under ISO 50001, which identifies areas within the Company that record significant use of energy to ensure process optimisation and optimal energy efficiency. This systemic approach makes it possible to focus more intensively on searching for new innovative solutions to limit, use and consume energy resources.

EC Radlin - heat for Silesia residents

On 25 September 2019, at JSW Group's Radlin coking plant, an agreement was reached ensuring supply of heat for the residents of Radlin and the mine KWK ROW Ruch Marcel. The project consists of the construction of a modern heat-and-power plant fuelled by treated cove oven gas, which will eventually replace Marcel CHP, owned by Polska Grupa Górnicza and expected to shut down at the end of 2022.

On 25 September 2019, at JSW Group's Radlin coking plant, an agreement was reached ensuring supply of heat for the residents of Radlin and the mine KWK ROW Ruch Marcel. The project consists of the construction of a modern heat-and-power plant fuelled by treated cove oven gas, which will eventually replace Marcel CHP, owned by Polska Grupa Górnicza and expected to shut down at the end of 2022.

The Radlin CHP will be a modern unit generating thermal and electric energy in cogeneration, i.e. in the most efficient way, in a single technological process. The Radlin CHP will meet the EU's requirements, especially the BAT conclusions for large combustion plants (BAT LCP). The Radlin CHP will meet the coking plant's energy demand, and excess electricity will be fed into the National Energy System. Heat in the form of heating water will be supplied for the purposes of PGG KWK ROW Ruch Marcel (21 MWt) and the residents of Radlin (16 MWt). The unit will use approx. 180 million cubic metres of coke oven gas per year.

JSW Group's investments considerably contribute to Silesia's development. Efficient cooperation between the government and local authorities can ensure that they are promptly implemented. Construction of the Radlin CHP is yet another example of good cooperation on multiple levels, with benefits for businesses, the region and its residents.

Incrase in energy efficiency of production processes - machinery and equipment

A range of tasks intended to improve the energy efficiency of production processes and decrease the energy intensity of machinery and equipment were performed in 2019. On-going investments in low-emission technologies include:

A range of tasks intended to improve the energy efficiency of production processes and decrease the energy intensity of machinery and equipment were performed in 2019. On-going investments in low-emission technologies include:

- construction of new cogeneration engines to produce electric and thermal energy based on methane from drainage at mines Budryk and Knurów-Szczygłowice,

- construction of new power-generation units using coke oven gas to produce electric and thermal energy in coking plants,

- modernisation of coking batteries,

- modernisation of air conditioning systems in underground excavations.

On-going tasks intended to improve efficiency are correlated with the process of obtaining energy efficiency certificates. The Act on energy efficiency of 20 May 2016 introduced a support mechanism (white certificates, which can be traded). Pursuant to the act, each energy customer in Poland who implements investments resulting in the savings of electric, thermal or gas energy can apply for white certificates.

The certificates can be obtained after performing the requisite procedures, i.e. energy efficiency audit and submission of an application to the President of the Energy Regulatory Office, and can then be sold on the power exchange Towarowa Giełda Energii to entities obligated to acquire and redeem them (all sellers of electricity, heat and gas to end-customers in Poland).

In 2018-2019, JSW submitted application to the President of the Energy Regulatory Office for the following undertakings (effect shown in tonnes of oil equivalent):

- Thermal modernisation of drying building at KWK Pniówek - expected effect 145.149 toe,

- Modernisation of external lighting on the surface at mine KWK Borynia-Zofiówka-Jastrzębie - expected effect 67.3 toe,

- Modernisation of external lighting by adapting it for modern LED lighting at KWK Knurów-Szczygłowice - expected effect 73.352 toe,

- System for recovery of energy from process gas at methane drainage station at mine Budryk - shaft VI Chudów, using a 2MW containerised cogeneration system:

- For electricity - expected effect 1 289.768 toe,

- For heat - expected effect 4 660.048 toe,

- System for processing waste gas from methane drainage at mine KWK Knurów - Szczygłowice Ruch Knurów, using 3x4MW cogeneration systems

- For electricity - expected effect 8 244.196 toe,

- For heat - expected effect 5 637.939 toe,

Applications for white certificates for new investments at KWK Budryk based on methane from mine drainage are currently being drafted:

- Construction of 2x4.0MWe cogeneration system at shaft VI,

- Construction of 2x4.0 +2.0MWe cogeneration system at the Main Entity.

In 2018, JSW KOKS submitted two applications to the President of the Energy Regulatory Office and one application in 2019 (effect shown in tonnes of oil equivalent):

- Modernisation of EF1 electrostatic precipitator together with modernisation of particulate matter transport installation - expected effect 84.621 toe.

The above tasks related to introducing modern technical solutions and comprehensive modernisation of older installations will improve the particulate matter transport system's operation and reduce demand for energy. Modern pneumatic transport devices reduce the use of technological air, which is used to transport particulate matter, and will spread demand for technological air for transport purposes over time.

In 2018-2019, PGWiR submitted applications to the President of the Energy Regulatory Office for an undertaking aimed at improving energy efficiency through the re-construction or repair of buildings. Modernisation of sorting and packing building façade through thermal modernisation of walls, partial replacement of façade and replacement of window sills for more energy-efficient ones - expected effect 94.310 toe and 10.580 toe (effect expressed in tonnes of oil equivalent).

Obtaining and selling white certificates partially refunds investment expenditures and thus encourages investment.

Continued activities intended to reducen greenhouse gas emissions, decrease the carbon footprint of the organisation and its products - coal and coke

For two years, we have been actively participating in Carbon Dioxide Units auctions organised by the State Forests as part of the Carbon Forests Project. Funds assigned for their purchase - as indicated by us - were used for a project at the Kobiór Forest District - Modernisation of educational pathway: "In the land of the Pszczyna bison."

For two years, we have been actively participating in Carbon Dioxide Units auctions organised by the State Forests as part of the Carbon Forests Project. Funds assigned for their purchase - as indicated by us - were used for a project at the Kobiór Forest District - Modernisation of educational pathway: "In the land of the Pszczyna bison."

In 2019, a Methane Emissions Team was formed with the intention to analyse ways to maximise the economic use of methane, improve the efficiency of mine drainage, reduce emissions from mining excavations and use methane from ventilation air.

The main source of greenhouse gas emissions from JSW Group's operations is methane from mining excavation ventilation systems (approx. 71% of total emissions expressed in CO2e). This is followed by CO2 from fuel combustion processes, mainly in the coking segment. Other greenhouse gas emissions and other pollution emitted into the air derive from the combustion of fuel in boilers, gas engines, combustion engines, surface and underground vehicles, equipment and machinery as well as from the process of cutting, welding, painting and operating cooling and air conditioning equipment.

The key to reducing JSW Group's greenhouse gas emissions is methane, its capture and economic use. As a result of using methane to generate electric and thermal energy in high-efficiency cogeneration, methane emissions in 2019 were reduced by approx. 76.9 million m3 (approx. 3% more than in 2018). The construction of additional engines using gas from mine drainage was continued in 2019 at the Budryk and Knurów-Szczygłowice mines, which will lead to a reduction in methane emissions by a total of approx. 1.6 million Mg CO2e.

In 2019, approx. 131.7 million m3 of methane was captured in JSW's mines, with methane drainage efficiency at about 35%, of which 76.9 million m3, i.e. approx. 58%, was economically used.

In the case of coke oven gas, on average 94.8% of the produced commodity was economically used in 2019, of which 28.9% was used in the energy area (generation of electric and thermal energy).

JSW Group's strategic objective is to reach energy self-sufficiency by 2030. In 2018, an investment project entitled "Economic use of methane" was launched. The project is scheduled for five years and concerns the Budryk and Knurów-Szczygłowice mines.

13 generators with total capacity of 48 MWe will be built as part of the project. Methane drainage and energy infrastructure will be expanded in order to complete this project. Investments related to the use of coke oven gas for the generation of electricity are also under-way at JSW KOKS. A 28 MWe power unit is under construction at Koksownia Radlin.

The generation of electricity from methane and coke oven gas will eventually meet JSW Group's demand for electricity. Provided that all of these investments are completed on time, the savings on electricity will reach PLN 807 million by 2030. Reducing methane emissions into the air and improving the efficiency of methane drainage are priorities for JSW SA, which is why on 9 January 2020 an agreement was signed with PGNiG SA on cooperation on the research project "Geo-metan II." The project is intended to obtain methane from the deposit prior to mining operations. The successful deployment of this project will largely increase operational safety and considerably reduce methane emissions into the air already during access and preparatory works.