Selected projects

2019 was a year of dynamic development in 11 research areas, the effects of which will play a major role in modernising the mining and coking sectors and enhancing occupational safety.

Last year, we significantly increase the scale of our R+D+I activities, as seen in the number of projects launched. We initiated 55 new R+D+I projects. At the end of the reporting period, JSW Group had a total of 71 R+D+I projects.

These projects are in defined research areas:

- exploitation of deposits,

- product quality,

- operational efficiency of mines,

- modern management models,

- heterogeneous telecommunications and ICT systems in workings,

- mine ventilation and air conditioning,

- occupational health and safety,

- environmental protection and development of environmental strategy,

- rehabilitation of post-mining areas,

- use of coal derivatives,

- disruptive technologies.

JSW Group's flagship innovative and R+D projects

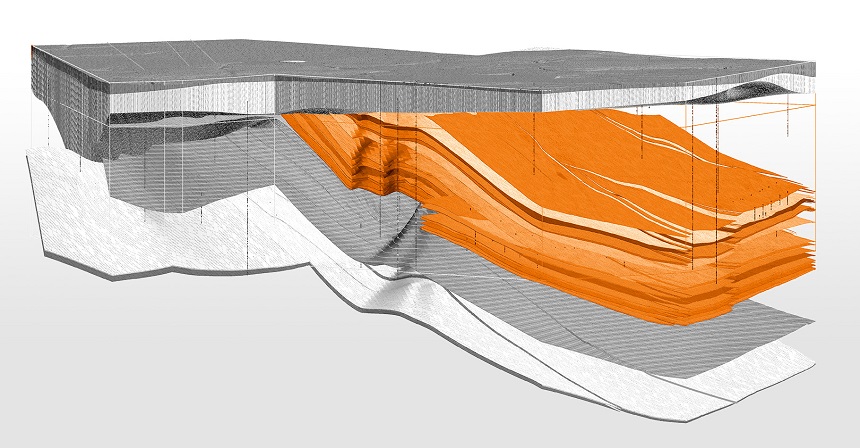

Deposit modelling and production planning at JSW

This project is aimed at optimising the production planning process, with particular emphasis on incorporating JSW Group's Strategy.

A system based on two global IT solutions was implemented as part of the project, which significantly modernised the deposit management and design processes at the mines. Similar systems are used by foreign mining groups in Australia or the U.S. So far in Poland, only LW Bogdanka and KGHM's mines used 3D models for production planning. JSW has now joined them.

A 3D model of a deposit is a graphic visualisation of its structure together with disruptions in it, created on the basis of information about the deposit. Adapting the mines' IT infrastructure for teamwork at measurement and geological divisions and production preparation divisions, along with data preparation and verification, constituted the basis for creating a 3D deposit model.

As a result of project work, a central geological database was developed at JSW's mines, with data from 250 surface wells, 1 440 underground wells, 14 670 walkway profiles, over 24 000 quality samples, 100 major faults and over 150 faults.

The outcome of this project includes structural and quality spatial models for deposits within JSW's mines as well as schedules for strategic production. The Company now has a schedule for the construction of 700km of designed walkways and 480 longwalls, including 50 types of roofbolt support systems and 25 algorithms for production restrictions.

Moreover, a visualisation of deposits and a modern 3D deposit model make it possible to better understand the variability of mining and geological conditions in mines, while the scheduling software makes it possible to better optimise production at JSW, including by creating various production scenarios at the mines.

RCM implementation

This innovative project is being implemented as part of JSW Group's IT/OT Strategy. Machine availability is expected to increase as a result of the project.

The project concerns: supplementing machines and equipment, expanding optic fibre network and software performing the monitoring of work parameters for machines and equipment, implementing a master monitoring system, creating a new organisational unit for maintaining the operation of monitoring systems. Systems that make equipment operation parameters available were deployed as part of this project.

A central data server was also launched, and the gathering and processing of data used in analysing the performance of machines and equipment were automated. Using this data will make it possible to optimise work times and the use of equipment at JSW's facilities.

Mobile medical point

Over the past decades, providing medical aid and access to it for the average citizen have undergone a revolution, ensuring the highest and commonly available medical standards to our citizens. Analysing this in the context of the mining industry's specific nature, JSW Innowacje, Central Mining Rescue Station and ITG KOMAG signed a memorandum intended to take steps that increase the safety of underground work. One of the objectives of this memorandum is a project to design a mobile medical point, an underground ambulance, which will make it possible to provide professional help to victims at the accident location. The formation of a mobile medical point and implementation of an innovative standard for providing medical aid will improve the mines' perception as a modern, innovative employer that ensures the highest employment standards.

Hydraulic roof bolters

This project is intended to validate the capacity to implement a cost-effective, efficient technology for mining operations that is safe and comfortable for the crew and applies roofbolt support technology for universal use in the geological and mining conditions found in the Upper Silesian Coal Basin. In October 2019, the first underground design works were carried out, followed by the construction of 173 running metres of a research heading on 31 December, intended to validate the technology's effectiveness and safety, which gives the Company grounds for expanding the use of roof bolters for preparatory and exploitation work at JSW Group's mines .

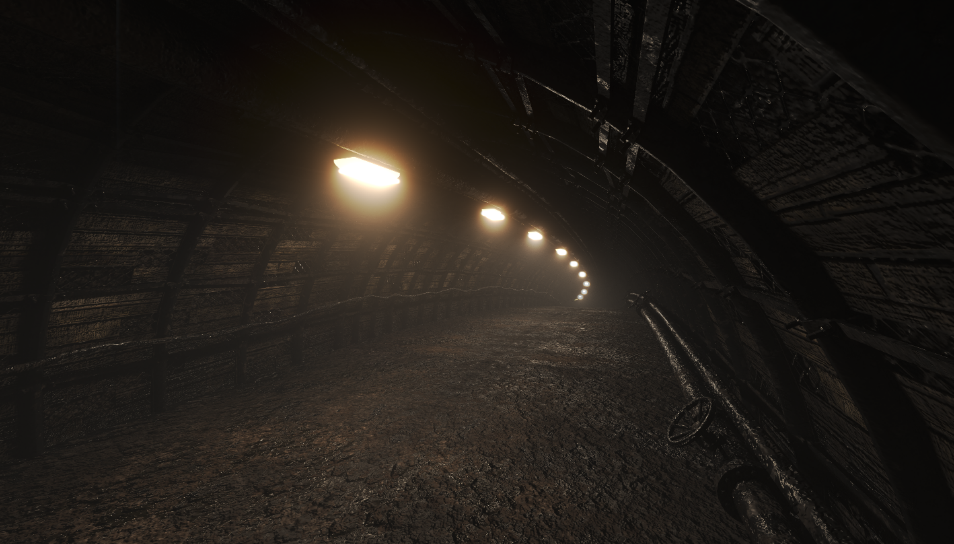

VR MINE

The main aim of this project is to prepare a technological demonstrator covering underground work stations that make it possible to perform a multi-person walk within a single virtual mine.

Initial models for generating mine sections and levels have already been developed. In 2019, a section of a walkway heading was modelled in 2019, with various variants of intersections, which then served as the basis for the mine's generator. In effect, a computer application was developed for generating a random mine and walking through it using virtual reality.

Additional works are being conducted using the designed environment in order to implement virtual elements of the surroundings and equipment, including bolter miners and roof bolters. It is currently possible to become a miner and travel in a suspended rail towards an excavation. Using a virtual controller, it is also possible to easily operate a longwall shearer and put out fires using an extinguisher.

This project serves to create the technological and infrastructural basis for additional projects developing this technology. The demonstrator will have capacity for development, with the addition of new equipment and software components (implementation of training scenarios - mining work, accidents, disasters, emergency rescue).

Optimisation of roof bolting systems for mine walkways at JSW S.A

This project is intended to evaluate the capacity for reducing operational costs by reducing costs related to drilling and maintaining walkways as well as a pilot implementation of the recommended solutions. The project is focusing on selecting potential excavations where it is possible to deploy the technological solutions, selecting optimal supports and constructing excavations, along with subsequent monitoring. This project currently is 40% complete.

Measurement devices have been or are being installed at KWK Pniówek, KWK Budryk and Ruch Szczygłowice in 2019. Hydraulic roofbolt systems are also being used in implementing this project at JSW's mines. This project will make it possible to maintain excavations for a longer time, which will improve mine safety and reduce the production costs of JSW's facilities.

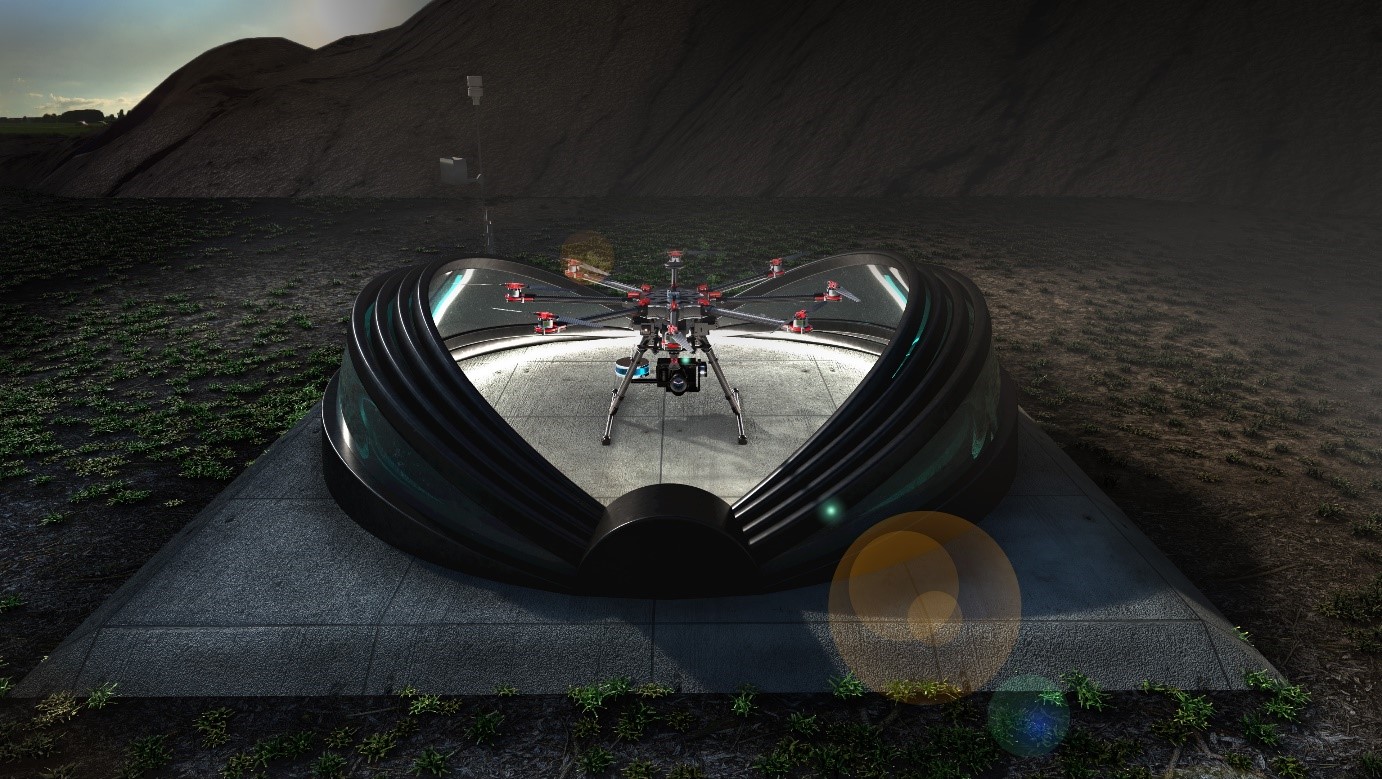

AutoInvent

AutoInvent is a research and development project aimed at developing an automatic system for acquiring and analysing spatial data, which will help in automating the inventory, 3D modelling and coal heaps calculation processes in quasi-real time. This project is intended to take measurements from air that are more precise and better quality, using unmanned platforms with photogrammetry and laser scanning. Reducing performance times will be achieved by automating the processing of measurement data and report compilation. A complete system will be developed as part of the AutoInvent project that automatically delivers reports on the quantity of resources in a coal heap in several hours from a report request. Precise inventory results will be generated with an innovative measurement method. Measurements will be taken by integrating photogrammetry data from HD cameras and laser scanning.

In 2019, as part of the AutoInvent project, the first group of research tasks was completed, aimed at validating the technical components of basic sub-systems in laboratory conditions. The second group of research tasks, consisting of validating technology by developing a system demonstrator, was commenced.

Construction of explosive materials storage site

Analysing the available know-how and following legislative changes, JSW Innowacje launched a project to develop a concept for and implement above-ground explosive materials storage sites.

The project is intended to design, build, test and operate innovative above-ground storage sites for explosive materials. The project incorporates legal, economic (explosives management) and environmental aspects, making it possible to adapt the explosives storage sites to the conditions present at the mining facilities, those existing and those currently being built. So far, explosives storage sites were situated in the vicinity of mining excavations, usually at each level - posing a multitude of problems of a legal nature as well as problems related to maintaining safety and economic feasibility.

UTM system for coordinating and managing UAV flights in Polish airspace

A UTM system is a tool for digitally coordinating UAV traffic and managing requests and permissions for flights in Polish airspace. These are operational solutions necessary for exercising civil aviation supervision and an ICT system. The functionalities embedded in the ICT system respond to the basic needs related to coordinating UAV traffic and managing flight requests and permits. The innovative portion of the UTM system involves developing the UTM system's functionalities and preparing the system for operational and commercial implementation.

The system's operational deployment will speed up the process of issuing UAV flight permits and conditions. Communication between UAV operators and Polish Air Navigation Services Agency personnel will also become more dynamic because the (electronic) UTM system is less burdensome and easier to use than manual flight coordination. It also includes analytical tools to verify the locations of planned UAV missions.

Tests conducted in 2019 for the UTM system were the last phase of tests before operational deployment. They consisted of performing the tasks of UAV operators and Polish Air Navigation Services Agency personnel in a digital environment using the UTM system's modules. The tests were carried out by Polish Air Navigation Services Agency units, flight controllers and airspace information personnel. The UTM system's functionalities were being developed during these tests. Production tests were intended to identify any potential irregularities and errors during continuous system operation over a longer period of time and with the use of all modules in the UTM system.

Deployment of software for simulating and designing ventilation

Proper ventilation is an essential process in mine operations and is fundamental to the safety of people working in underground excavations. From a ventilation safety viewpoint, the most significant natural threats include the methane hazard, fire and gas and rock bursts. The ability to simulate airflow processes in mining excavations is important mainly because it allows process management and quick response in emergencies.

The system makes it possible to simulate ventilation processes in underground mines and allows 3D visualisations showing actual dimensions and shapes of ventilation ducts and the gas processes taking place there.

Deploying VentSim is intended to:

- effectively regulate airflow in the ventilation network,

- simulate: underground fires, gas bursts and leaks, impact of rock bursts on the ventilation network, time necessary for clearing post-detonation gases, forecasting the impact of combustion rail on air in the mine,

- forecast climate conditions and conduct on-going monitoring and analysis based on measurements from telemetric sensors,

- design escape routes,

- conduct multi-dimensional simulation of airflow in newly-designed mine sections and assist in selecting optimal solutions in terms of ventilation,

- in the case of a fire threat, quickly present the potential migrations of air through "old" goafs,

- the embedded module VentLog makes it possible to archive ventilation measurements performed by ventilation staff and to visualise these in the mine model,

- during emergency operations, it is possible to present the real-time situation in a mine model at the operational HQ and simulate changes in ventilation proposed by the operation leader prior to issuing orders to emergency crews.

Development of methodology for manufacturing innovative products

This project, commenced in 2019 and completed in February 2020, consisted of developing methodology for manufacturing innovative matrix products, certificate reference materials (CRM), which are used in research and analysis of solid fuels (hard coal). The outcome of this research and development work is the first of its type product made in Poland that also has a set of unique properties, i.e. values assigned (certified) to five key parameters: sulphur content, ash content, mercury content and two additional metals.

Credible information on the quality of coal obtained by using CRM is key in commercial settlements and the on-going monitoring of mining production. Planning, production and distribution of CRMs are performed in line with the standard PN-EN ISO 17034:2017-03. The competences of CLP-B Sp. z o.o. are confirmed with an accreditation certificate received in 2018 from the Polish Accreditation Centre - RM 001 (first accreditation in Poland), and these products are innovative at least on a national scale. The only coal CRMs currently available on the market are made abroad. This is a product adapted to the specifics of the domestic solid fuels market, and especially research labs that perform solid fuel analyses for the energy and coking sectors.