Concern for climate

Keeping in mind the nature of JSW Group's activities, undertaking activities related to respecting non-renewable natural resources is exceptionally important due to their scarcity. This entails their efficient acquisition, processing and use at each stage of the economic value creation process.

The Group exercises continuous oversight and monitoring as well as focuses on maximally reducing the scale of pollution reaching the environment and takes steps essential to optimally manage natural environment areas and resources.

Operating in the extractive industry also entails a large indirect impact on the use of natural resources, generation of waste, consumption of energy and fuels and emissions into the air. Coal mining is inextricably accompanied by methane as an associated mineral that constitutes a greenhouse gas which impacts our climate. Methane emissions constitute approx. 74% of JSW Group's total greenhouse gas emissions, expressed in CO2 equivalent.

JSW strives to maximise its capture and use but due to miner safety concerns it is not possible to avoid it being emitted along with ventilation air from exhaust shafts.

JSW Group has direct and indirect impact on climate changes:

- DIRECT IMPACT on climate change results from its mining and production operations that generate methane emissions in the case of coal mining and CO2 in the case of coke production and energy generation.

- INDIRECT IMPACT on climate change is mainly related to the processes of transporting commodities, materials and products, the energy-intensity of the production process and the management of extractive waste.

Impact of climate change on JSW Group

Climate changes may have an impact on the Group's activities in the form of adverse, variable weather conditions that can cause disruptions in mining, production and product deliveries to customers and in supplying essential production materials to the Group's facilities.

Drought can have a particular impact by preventing water abstraction for production purposes and discharging salted mining water to surface waters. Higher temperatures in the summer may also have an impact on ventilation and air-conditions systems in mining excavations. Coking plants, as continuous-operation facilities in which pausing the production process would result in damages, are particularly exposed to weather changes.

The current policy for transitioning to a low-emission economy and the European Green Deal objectives for reaching climate neutrality by 2050 may lead to a reduction in fossil fuel mining and use. In connection with this, legislative and regulatory initiatives at domestic and EU level can have a material impact on JSW Group.

Actions undertaken in 2020

JSW, in cooperation with scientific institutions, has started to prepare a Roadmap regarding the impact of climate changes on Group operations, strategy, investment decisions and assets, efficiency, market and society. It has defined the key directions of efforts aimed at preventing climate changes:

- looking for technological, process and legal solutions which will support prevention of climate changes,

- efficient utilization of natural resources,

- optimization of the energy intensity of the operations through maximizing self-generation of energy,

- increasing the share of RES in energy production (photovoltaics),

- increasing energy efficiency of production processes – machinery and equipment,

- continuation of efforts aimed at reducing greenhouse gas emissions, reducing the carbon footprint and individual products – coal and coke.

In 2020, JSW formed the Technical Team for drafting the JSW Climate Policy and, taking into consideration the guidelines of the Task Force on Climate-related Financial Disclosures („TCFD”), it has the following tasks: specify management supervision of climate-related issues, define risks and opportunities connected with climate changes and their impact on the business model, strategy and plans of financing the company, analyze the influence of climate changes on the activity of mines and coking plants and prepare a plan for adapting to climate changes, define an action plan for moving towards low-carbon production, define key ratios and reduction targets for greenhouse gases in the short, long and medium term. In 2020, the implementation of tasks aimed at reducing greenhouse gas emissions and improving the energy efficiency of production processes and reducing the energy consumption of machinery and equipment was continued.

In 2020 the execution continued of tasks to reduce the greenhouse gas emissions and improve energy efficiency of the production processes and reduce the energy intensity of machinery and equipment.The investments in low-emission technologies under way include, among others, installation of new co-generation engines for production of electricity and heat powered by methane drained in the Budryk and Knurów-Szczygłowice mines, construction of new power units using coke oven gas for production of electricity and heat in coking plants, modernization of coke oven batteries and modernization of the air-conditioning systems in underground mining pits.

Within the Group, in 2020, photovoltaic panels with the capacity of 0.7 MWp were installed at JZR.

For three years we have been taking part in auctions of CO2 emission allowances held by the Polish State Forests under the Forest Carbon Farms project. We purchased a gross total of 14,000 Carbon Dioxide Units (CDU) for PLN 152.0 thousand. Each purchased unit corresponds to 1 ton of emitted CO2. In line with the concept of Forest Carbon Farms, it enabled us to support a project implemented in our region in the Kobiór Forestry Region, in the Bison Reserve in Jankowice Pszczyńskie, entitled “Modernization of Educational Path: in the Land of the Pszczyna Bison”. Without participation, the 1st stage of the project adapted the existing path to the needs of people with disabilities, and erect items of the so-called “small architecture”, wooden footbridges and an information board. The total costs of this stage was approximately PLN 300.0 thousand.

Risks and opportunities associated with the climate and reponsibility

As part of the comprehensive approach to risk management, risks associated with climate changes, included in environmental risks, have been identified. They are subject to regular review and assessment by appointed risk owners. The risks are presented in Section 9.5 of this report.

Pursuant to the TCFD recommendations, the appointed Climate Policy Team has performed preliminary identification and assessment of two categories of climate threats and opportunities in the context of the diversity of the Group’s activities, including in production processes, operations and the supply chain:

- the risk of material physical impact (climate risks) - whereby the impact of climate change on the Group’s activities has been analyzed, including the frequency of heat (hot weather) waves, periods of drought, intensification of extreme weather phenomena - storms, violent storms, floods and flooding. The analysis also included emergence of invasive species from other climate zones which are carriers of infectious diseases, as well as the increased threat of forest fires;

- the risk associated with the transition to the low-emission economy, including:

|

Technological, market and product risks ensuing from the energy transformation, the new climate policy - i.e. raising of the reduction limits planned by 2030 and the objective of achieving climate neutrality by 2050, increase in profitability - and, consequently - the share of alternative steel production methods - the hydrogen-based technologies, CCS, CCU. |

Regulatory risks associated with full implementation of the European Green Deal and its ancillary documents, the change of the pricing mechanism for greenhouse gas emissions, new sectors being included in the EU ETS system. |

Commitment to reduction of climate change

The current economic development policy of the European Union places particularly strong emphasis on climate issues, specified in the European Green Deal and ancillary documents, which in effect signifies the requirement to transition the industry towards a low-emission economy. As a producer of direct and indirect emissions of greenhouse gases in connection with the nature of our business and value chain, we are committed to the implementation of the objectives of the Paris Agreement and the European Green Deal. We are aware that our production processes cause high energy consumption and emissions into the air and water. We have to face these challenges in the near future and reduce them. The metallurgical (coking) coal and coke we produce still continue to be the key raw material for the production of steel used in the creation and implementation of low-emission technology and infrastructure. For example, to build a typical wind turbine uses about 180 tons of steel, which in turn requires about 100 tons of metallurgical (coking) coal to produce.Metallurgical (coking) coal has been included for the third time on the list of the EU’s critical raw materials, i.e. raw material for which supply shortages and their effects have a greater impact on the economy than shortages of other materials (COM(2020) 474).

In order to ensure a better quality of life in a situation of an ever growing global demand for materials and energy, it becomes necessary to use materials that have been produced both economically as well as sustainably, at lower emission levels and with due respect of local communities. We want to be a part of that solution in which we perceive challenges and opportunities.

In our approach to climate change, we try to follow international standards, including the guidelines of the Task Force on Climate-related Financial Disclosures and UN SDG 13. In 2020, we started the process of benchmarking our approach to climate change and, in a broader context, sustainable development in respect of the TCFD recommendations.

In the JSW Group Strategy for 2020-2030, revised in 2020, we have adopted the principal directions of JSW’s actions in the area of counteracting climate change: search for low-emission technological solutions, efficient use of resources, optimization of energy intensity of operating activities, increased energy efficiency.

We are developing the Group’s environmental strategy, designed to ensure interconnections between the business strategy and the new strategic objectives of the European Union, with reference to, among others, the criteria laid down in the Regulation of the European Parliament and the Council on the establishment of a framework to facilitate sustainable investment, the so-called Taxonomy, with a special emphasis on the issues of achieving climate neutrality, lowering of emissions and creating a circular flow of raw materials.

Since 2017, we have calculated the carbon footprint of the Group, which included direct and indirect greenhouse emissions involved in both the mining and coke production. The main source of greenhouse gas emissions from the Group’s operations is methane, which is removed for safety reasons from mining pits (approx. 74% of the carbon footprint). The key to lower methane emissions is capturing and economic utilization to generate energy. At present, we ensure utilization of approx. 86 million m3 of methane, which is equivalent to approx. 1.73 million tons of carbon dioxide.

Since 2018, in the Budryk and Knurów-Szczygłowice mines we implement an investment project entitled: “Economic utilization of methane” of the total project value of approx. PLN 300 million, designed to increase the share of in-house energy and reduce methane emissions and the carbon footprint by further 1.3 Mg CO2e.

JSW KOKS S.A. implements environmental investment projects related to the use of coke oven gas for electricity generation. In the Radlin Coking Plant, an energy generation unit is under construction, of the capacity of 28 MWe. The excess coke oven gas will be used for production of electricity and thermal energy for internal use and for sale.

To respond to the high energy intensity of water desalination, the PGWiR company, involved in the management of saline water from JSW coal mines, plans to build a large photovoltaic farm of the capacity of 3.1 MWp in the area of the Dębieńsko Desalination Plant. The idea is for the green energy generated by the photovoltaic farm to power the Dębieńsko Desalination Plant, where mining water will be treated to the parameters of technological water, and then recirculated to be used in the Budryk mine.

Other activities with the aim to reduce emissions of other greenhouse gases are undertaken, as well. These include modernization of the underground mining pits air conditioning, as well as projects designed to improve energy efficiency and correlated with the process of acquiring energy efficiency certificates (the so-called white certificates).

Through JSW Innowacje, we participate in many research and development measures, with the aim to transition to a low-emission and circular economy. The most important of these projects is the development of a technology for separation of hydrogen from coke oven gas being a by-product of coke production, and the projects on technologies of CO2 reduction or capture of methane from ventilation air.

a. GASES AND DUST EMISSIONS

The main source of greenhouse gas emissions following from the Group’s operations is methane from the ventilation of mining pits (approx. 74% of total emissions, converted into CO2e) and carbon dioxide from fuel burning processes, mainly in the coke segment. Curtailing greenhouse gas emissions in the Group was accomplished by making the maximum energy utilization of gas through methane drainage in the mines. As a result of utilization of captured methane for production of electricity and heat in high-efficiency cogeneration systems, in 2020 the emission of methane into the atmosphere was reduced by approx. 86.0 million m3 (approx. 11.8% more than in 2019). In 2020 the construction of further engines running on gas from methane drainage in the Budryk and Knurów-Szczygłowice mines were continued. Upon completion they will make it possible to reduce methane emissions in total by approx. 1.3 million Mg CO2e.

In the coke segment, execution of the strategic projects launched in 2019 – modernization of the coke oven battery in the Przyjaźń Coking Plant and construction of a power unit in the Radlin Coking Plant – will make it possible to maximize the use of coke oven gas and improve energy efficiency. Excess coke oven gas is used for production of electricity and thermal energy for internal use and for sale. In connection with the participation of JSW KOKS in the greenhouse gas emissions trading system in reference to carbon dioxide, the Group carries out estimations of the cost increase that it will have to incur in connection with the operation of its coking installations, heat generation plants and combined heat and power plants in the fourth settlement period of 2021-2030.

CARBON FOOTPRINT

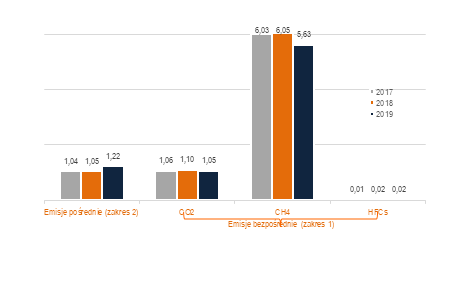

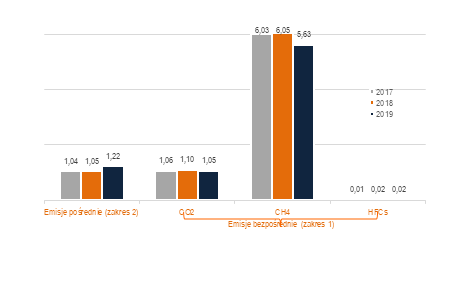

The Group is among the few groups in Poland that has been carrying out (since 2017) integrated estimation of the carbon footprint of the organization and two key products – coal and coke, using an implemented tool supporting the calculations. The calculations take into account emissions of the following greenhouse gases: carbon dioxide, methane and hydrofluorocarbons. The calculations were carried out in accordance with the GHG Protocol Corporate Standard and GHG Protocol Product Standard based on the emission intensity indicators published by the National Center of Emission Balancing and Management (KOBiZE) and the GWP (global warming potential) greenhouse effect creation indicators in IPCC Fifth Report from 2014. Scope 2 reporting in accordance with the GHG Protocol methodology is location-based – emission indicators published by the KOBiZE Center.

The Group chose the operational control approach. The JSW Management Board decided to publish information on the organization’s carbon footprint. The carbon footprint of coal and coke products calculated in scopes 1, 2 and 3 upstream will be made available on the express request of the Group’s business partners for such products.

Scope 1included direct emissions from sources located in all Group companies, comprising emissions:

- from burning of fuel in stationary sources,

- from technological processes, including: emissions from coking, emissions associated with ventilation, emissions from generation of cooling, emissions from other processes (e.g. welding),

- from burning of fuel in combustion engines.

Indirect emissions from scope 2 comprise emissions associated with generation of: electricity, heating, cooling and compressed air purchased and consumed by Group companies.

No biogenic emissions were recorded in 2020.

|

ORGANISATION’S CF JSW GROUP |

DIRECT EMISSIONS (SCOPE 1) | INDIRECT EMISSIONS (SCOPE 2) LOCATION BASED |

TOTAL EMISSIONS (SCOPE 1+2) |

||||

|---|---|---|---|---|---|---|---|

| EMISSIONS PER PRODUCT UNIT (COAL + COKE) |

EMISSIONS PER PLN 1 MILLION OF REVENUE |

||||||

| YEAR | mt Mg CO2e | CO2 | CH4 | HFCs | mln Mg/mln Mg | mln Mg/mln zł | |

| 2017 | 8,14 | 1,06 | 6,03 | 0,01 | 1,04 | 0,458 | 0,000917 |

| 2018 | 8,22 | 1,10 | 6,05 | 0,02 | 1,05 | 0,447 | 0,000838 |

| 2019 | 7,92 | 1,05 | 5,63 | 0,02 | 1,22 | 0,443 | 0,000914 |

| 2020 | 7,18 | 1,13 | 5,32 | 0,02 | 0,71 | 0,406 | 0,001027 |

Operational boundaries – direct and indirect emissions in scopes 1 and 2 Due to the fact that both coal and coke constitute intermediate products in further processes, scope 3 in the organization’s carbon footprint was omitted.

In accordance with the methodology recommended by the GHG Protocol, uncertainty of the organization’s carbon footprint was set at 8%.

JSW GROUP’S CARBON FOOTPRINT 2020

RESULTS ACHIEVED IN 2020

In 2020, the Group’s total emissions within scopes 1+2 dropped by 11.8% compared to the base year, with emissions from scope 1 decreasing by 8.9% and emissions from scope 2 – by 32.0%.

The major factor of emission reduction in 2020 was the lower, by 49%, purchases of energy from external suppliers, which were replaced by energy generated by the Group from units installed in-house. The achieved reduction of greenhouse gas emissions was almost 432 thousand Mg CO2e lower (as compared to 2019). Another factor was lower methane emissions from JSW mines by approx. 312 thousand Mg CO2e (as compared to 2019), achieved by the way of, among others, increased methane utilization for energy generation.

In comparison to 2019, CO2 emissions increased by 7.6%, attributable to the coking process and mounting of new engines fired with methane drainage gas from JSW mines.

OTHER ATMOSPHERIC EMISSIONS

Other substances emitted mainly as a result of: burning of fuel in boilers, gas engines, combustion engines in means of surface and underground transport and machinery and equipment do not cause breaches of the permissible levels or benchmarks.

| OTHER EMISSIONS (JSW GROUP) (MG) | 2020 | 2019 | 2018 |

|---|---|---|---|

| MASS OF OTHER ATMOSPHERIC EMISSIONS, INCLUDING: | 6478,0 | 6 763,8 | 7 935,8 |

| SOx | 1390,0 | 1 600,3 | 1 772,6 |

| NOx | 2352,1 | 2 479,7 | 2 851,0 |

| CO | 2309,8 | 2 312,1 | 2 870,5 |

| Total dust | 426,1 | 371,7 | 441,7 |

| OTHER ATMOSPHERIC EMISSIONS PER UNIT OF REVENUE – MG/PLN M | 0,93 | 0,78 | 0,81 |

JSW named as "Climate-Aware Company"

In the second edition of the "Corporate Climate Crisis Awareness Study," carried out by the Reporting Standards Foundation, Associations of Listed Companies and Bureau Veritas Polska, six listed companies received the title of "Climate-Aware Company." This included Jastrzębska Spółka Węglowa. The following companies were also in this group: MOL, LPP, LUG, CCC and Orange Polska.

The study examined the annual reports of all listed companies subject to mandatory disclosure of non-financial information for 2019. In line with European Commission guidelines, this was mandatory for 151 companies listed on the Warsaw Stock Exchange. Report content was analysed in terms of 10 criteria. Three of them concerned company policy or strategy in reference to managing climate crisis-related matters and identifying risks and opportunities related to climate change, while the remaining seven concerned greenhouse gas emission reporting.A "climate-aware" company knows what challenges climate change entails, has appropriate policy or strategy for limiting its impact on the environment and meticulously reports greenhouse gas emissions. "Climate responsibility" applies only once a company actually reduces its environmental impact and is on its way to reducing greenhouse gas emissions to zero.

The study revealed that the average score for the 151 analysed companies was 1.87 out of 10 (up from 1.03 points in the preceding year), with six companies: MOL, LPP, LUG, JSW, CCC and Orange Polska receiving the Climate-Aware Company title after scoring more than 70% of the available points, and the best company received 9.33 points (in the previous year, it was 7.33 points). 49 companies did not score even a fraction of a point (last year 66 companies scored 0 points), while the average score in the study of reports for 2019 was 1.87 points (out of 10) and was 0.84 points higher than last year.

b. EFFECTIVE USE OF NON-RENEWABLE RESOURCES

From the viewpoint of the environment, and climate in particular, JSW Group's most important activities are related to respect for non-renewable natural resources, meaning a more effective way to acquire, process and use them at each stage of the value-add process. JSW's planned use of coal is presented in a document entitled Deposit management project. This document is prepared by a mining enterprise and, once agreed with the regulator, is sent to the Ministry of the Environment for approval. Based on the size of the resource base and the deposit management plan, the enterprise applies for successive production periods under a mining concession for each mine being part of the parent company's organisational structure. Mine life-cycles and resource volumes are presented in point 2.4 of this report.

As regards the coking business, the most important project related to the effective use of non-renewable resources is the project to "build a power unit at Koksownia Radlin," which is one of the elements in the long-term operational strategy of JSW KOKS and the entire Group. The project encompasses the construction of a heat-and-power plant that will generate heat and electricity in high-efficiency cogeneration. The main fuel will be coke oven gas from JSW KOKS, and for safety reasons light fuel oil will be a backup fuel. The main fuel will be combusted at the rate of 21 000 Nm3/h, with the possibility of overloading up to 110%, which will make it possible to use up all of the excess coke oven gas, which will practically eliminate the need for gas flaring. The energy unit will constitute the main source of technological heat and electricity for Koksownia Radlin, making the coking plant self-sufficient in terms of energy, and will deliver heat to the district heating network to which municipal customers (City of Radlin) and industrial entities (Polska Grupa Górnicza S.A. KWK ROW - Ruch Marcel) are connected. Excess electricity left over after supplying Koksownia Radlin and other JSW KOKS facilities will be sold on market terms.

This investment meets the definition of an undertaking intended to improve energy efficiency, as specified in the Act of 20 May 2016 on energy efficiency. For this reason, an energy efficiency audit was commissioned and performed at JSW KOKS by a renowned expert firm in this field. The audit showed considerable savings in final energy consumption.

c. ENERGETIC EFFICIENCY

The generation of electricity from methane and coke oven gas will eventually meet JSW Group's demand for electricity. Provided that all of these investments are completed on time, the savings on electricity will reach PLN 807 million by 2030. It should be emphasised that electricity purchased from external vendors in 2020 was down by 49% (in comparison with 2017), and it was being replaced with energy from generating assets installed at JSW Group.

In the coking segment, implementation of the strategic tasks launched in 2019 - modernisation of a coking battery at Koksownia Przyjaźń and construction of a power-generation unit at Koksownia Radlin - will maximise coke oven gas utilisation and improve energy efficiency. Excess coke oven gas is used to produce electric and thermal energy for both internal use and for sale.

At PGWiR, which is in charge of utilising saline water from JSW's mines, because of the high energy-intensity of the water desalination process, a photovoltaic farm is planned to be built at the Desalination Facility in Dębieńsko (Czerwionka-Leszczyny) with capacity of 3.1 MWp. Under this concept, the green energy generated at the PV farm will be used at the Dębieńsko desalination facility, where mine water will be improved up to technological water parameters and subsequently returned to circulation and used at the Budryk mine. Mandatory corporate approvals are necessary for this investment to go ahead in accordance with JSW S.A.'s regulations.

Activities are also being undertaken in order to reduce the emissions of other greenhouse gases. This includes the modernisation of air conditioning systems in underground excavations and activities intended to improve energy efficiency, correlated with the process of acquiring energy-efficiency certificates ("white certificates").

Use of fuels in energy generation at JSW Group

| ITEM | 2020 | 2019 | 2018 |

|---|---|---|---|

| Motor gasoline (litre) | 248 822,5 | 209 632,7 | 175 150,4 |

| Diesel fuel (ON) (litre) | 8 993 119,8 | 8 764 585,3 | 7 906 184,3 |

| LPG (litre) | 53 194,1 | 49 369,9 | 57 794,3 |

| Methane from mine drainage (m3) | 29 449 991,1 | 20 460 602,0 | 18 732 816,0 |

| Coke oven gas (m3) | 1 182 099 878,0 | 1 197 775 911,0 | 1 327 904 234,0 |

| Heating oil (Mg) | 40,6 | 2 709,5 | 57,4 |

| Hard coal (for energy purposes) (Mg) | 116,6 | 105,5 | 109,1 |

| Waste gas fuel (excess gas) (GJ) | 92 052,6 | 105 138,0 | 125 723,0 |

| Natural gas (m3) | 576 754,0 | 622 008,2 | 83 977,0 |

Use of energy sources at JSW

| unit of measure | 2020 | 2019 | 2018 | |

|---|---|---|---|---|

| Electricity | GWh | 1080,5 | 1 056,7 | 1 026,7 |

| including own production | GWh | 99,8 | 78,0 | 70,7 |

| Heat | TJ | 845,6 | 818,2 | 769,2 |

| including own production | TJ | 16,6 | 74,2 | 78,3 |

| Other* | TJ | 542,8 | 608,5 | 608 |

| Total energy consumption | GJ | 5278,2 | 5 230,8 | 5 073,3 |

| Energy intensity index | MJ/Mg | 366 | 354 | 338 |

1 GWh = 3600 GJ

consumption = purchase + own production - sales