Selected projects

2020 was a year of dynamic development in 11 research areas, the effects of which will play a key role in modernising the mining and coking sectors and enhancing occupational safety.

Last year, JSW Group continued most of its research and development projects, with a total of 49 R+D+I projects in progress at the end of 2020. In this time, we also initiated 14 new R+D+I projects.

These projects are in defined research areas:

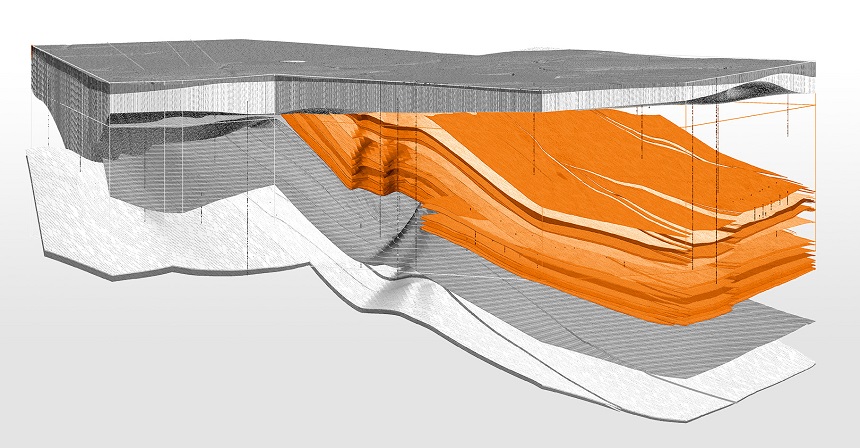

- exploitation of deposits,

- product quality,

- operational efficiency of mines,

- modern management models,

- heterogeneous telecommunications and ICT systems in workings ,

- mine ventilation and air conditioning,

- occupational health and safety,

- environmental protection and development of environmental strategy,

- rehabilitation of post-mining areas,

- use of coal derivatives,

- disruptive technologies.

KEY INNOVATION AND RESEARCH & DEVELOPMENT PROJECTS CARRIED OUT BY THE GROUP

Independent Rockbolt Support

The project is executed to significantly increase efficiency of roadway work, by developing and implementing a technology of conducting mining work using the bolting technique in the system of continuous mining and installation of independent rockbolt supports suitable to the conditions, in coking coal mines with a methane hazard in Poland.

Construction of an explosives store

The aim of the project is to build a store of explosive materials on the surface. The innovation of the project is associated with the location of the stores. So far explosives stores were built underground on each of the mining levels. The cost of construction of a store on the surface is many times cheaper and such store can be used until the decommissioning of the mine.

Implementation of a research section of the Independent Rockbolt Support in KWK Pniówek

The project involves optimization of the dimensions of the pits from the perspective of resilience to rock mass tensions and replacement of the passive arch and frame support with an active rockbolt support, following positive results of the preliminary analysis of the possibility of execution of a rock and coal pit section using this support.

Optimization of roadway excavation support systems at JSW

The project is executed under the “Efficiency” program whose level of progress is 40%. Metering devices were or are being installed in the Pniówek and Budryk mines and the Szczygłowice Section. In addition, implementation of the mechanical lining technology in JSW mines is under way. The project will make it possible to, among others, maintain the pits for longer, which will improve the safety and reduce the production costs of JSW mines.

AutoInvent

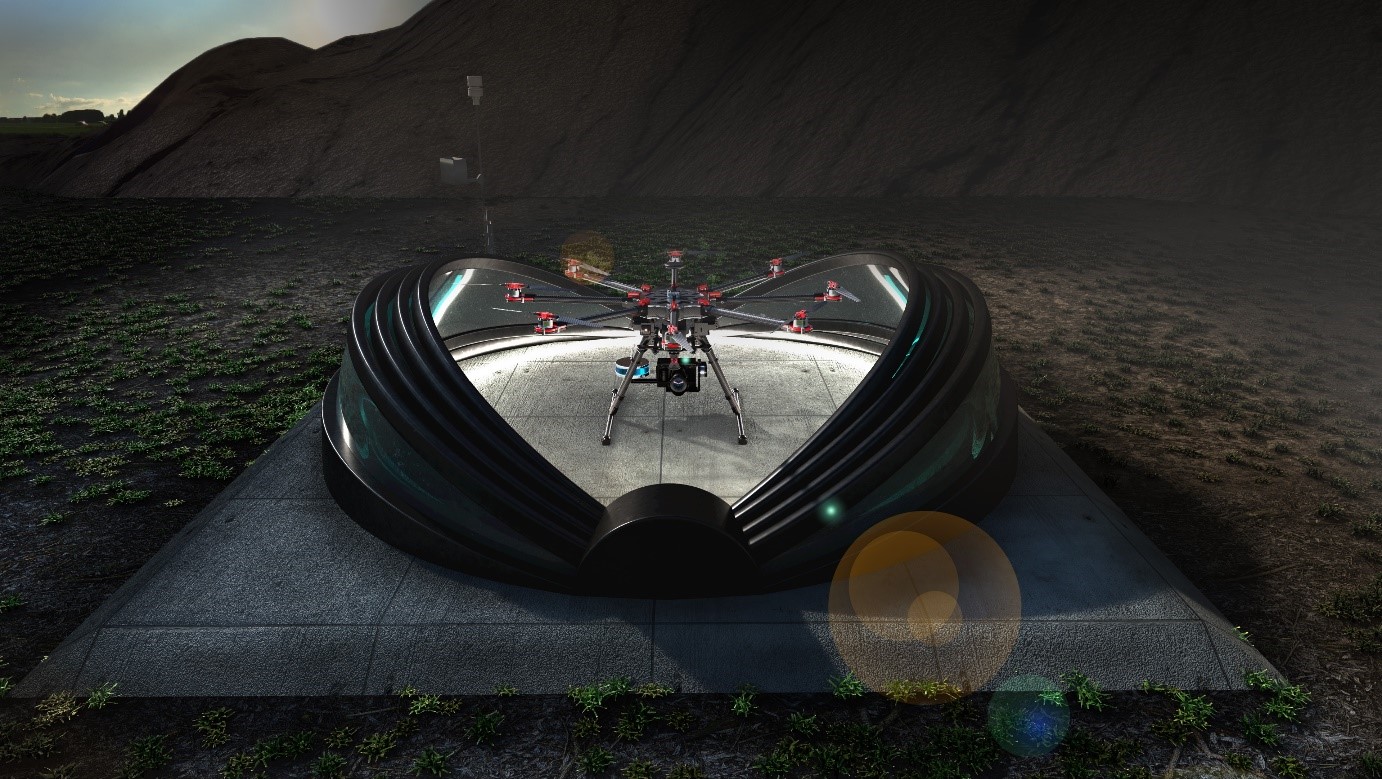

The main objective of the AutoInvent project is to develop an automatic, multi-sensor unmanned aircraft system. The most important task of the system will be to automate the process of cyclic inventory measurements of mineral resources which must be performed frequently, several times per year. The merger of innovative measurement technologies will be used: 3D scanning and close-range photogrammetry and integration of two methods of precise positioning: GNSS satellite measurements supported by corrections from RTN and precise TPS laser measurements. Using the merger of data and laser scanning technology with close-range photogrammetry allows for increasing significantly the data accuracy, shortening simultaneously the time needed for field work. In addition, the use of non-invasive measurement methods in an automated process improves the safety of workers. The project deliverables as services provided with the use of an innovative solution will be introduced to streamline the process of performing inventory measurements.

DensiCoal

The aim of the project is to develop technology for the production of coke charge component through compacting coal blends containing fine coal fractions (FCF). The basic research works will be conducted at a laboratory, big-laboratory, pilot and industrial scales. Based on the assessment of the impact of individual variables (e.g. composition and properties of the compacted blend, compacting technique and parameters, share of the compacted material in the coke charge) on the quality of the compaction product and using it to produce coke, assumptions for the pilot project of an installation using the DensiCoal technology will be prepared. On this basis a pilot installation with the capacity of 5 Mg/h will be designed and built. The final element of the research will be to verify the adopted solutions during tests of producing the compacted product at a pilot scale and industrial tests of coking the coal blend with produced component. The research will be completed with a technical and economic analysis of the industrial scale implementation of the technology. The DensiCoal technology is planned to be implemented in the Przyjaźń Coking Plant.

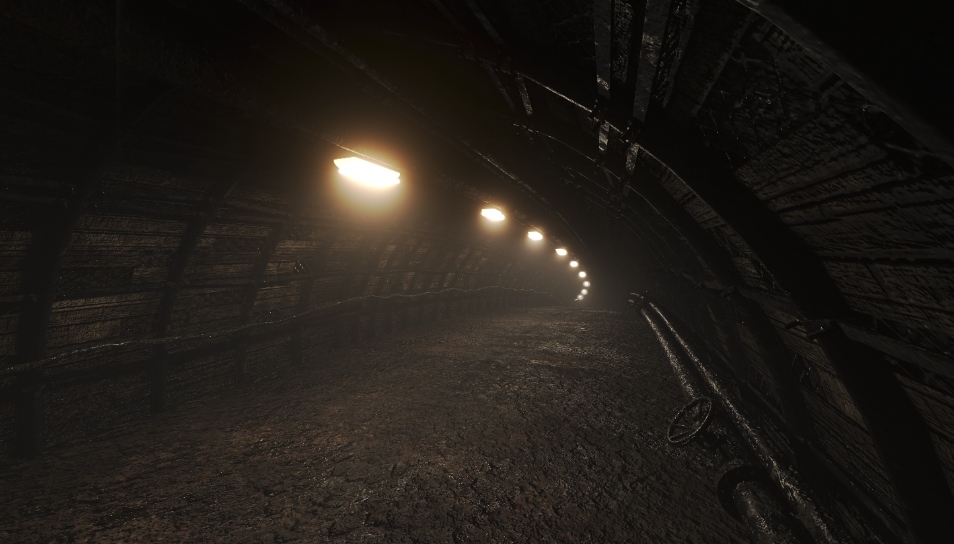

SENSE VR

The objective of the SENSE VR project is to develop the methodology of training miners based on using a VR adaptive network environment. Within the development works, the Consortium prepares a demonstrator of the VR adaptive environment for miners, which will include branching training scenarios. The effect of the SENSE VR project will be: in the technological area – a demonstrator of the VR environment with equipment at level VIII of technological readiness, in the commercial area – implementation of an optimized process of miner training to the activity of JSW SIG and raising the work safety level in the Group. The method will be potentially implemented also in other branches of heavy and/or mining industry.

HEET II

The purpose of the HEET II project is to enhance the standards of miners’ work and power safety in the mines as well as in other industries and public services. The four main issues implemented in the project (single line transmission of energy, wireless transmission of energy, monitoring, management and communication, integrated composite single-bar route) clearly represent an innovative solution for a highly efficient and safe system for the transmission of electricity.

ImproStamp

The purpose of the project is to develop and verify the technology for stamp charging with increased mechanical strength over the stamp charges that are currently produced, which will make it possible to reduce by at least 60% the quantity of destruction of coal cakes during coke oven charging. The improvement in the mechanical strength of stamp charging will be achieved by introducing a chemical additive to the feedstock blend to affect the strength of interparticle interactions, and thereby on the process of reorgnizing grains during the stamp charging operation. Development work will be done in the Radlin Coking Plant.

Development, accreditation and sales of a UTM system (Unmanned Aircraft System Traffic Management

The UTM system is a tool for digital coordination of the flights of unmanned aircraft and management of requests and consents for flights in Poland’s air space. These are operational solutions required for execution of tasks by civil aviation supervision services and the ICT system.

Development of a system to manage SBSP flights

Design of an ICT system to manage SBSP flights (systems/platforms of unmanned aircraft) in the specified Geographic Zone defined under the Commission’s Executive Regulation (EU) 2019/947 of 24 May 2019 also referred to as a DTM system (Drone Traffic Management), or a system for the local management of the flights of unmanned aircraft in a specific volume of air space.

Implementation of an Electronic Document Circulation System

Project to digitalize and streamline business processes relating to workflow. The production launch for handling investment applications and office handling of documents took place in the Office of the JSW Management Board.

Implementation of a smart OCR recognition system

Implementation of an OCR tool to streamline the process and automate the processing of financial documents.

Modernization of the control center

Modernization of the offices of the Rescue Campaign Management Teams in KWK Borynia-Zofiówka. An overall concept for the operation of the control center was devised for KWK Pniówek on an IT/OT basis.

Building a data warehouse and big data platform for the OT area

As a result of project execution, the data model has been defined, as have been the principal interfaces for data collection from the OT area. For the purpose of implementation, the available solutions have been scrutinized and the decision has been made to purchase and implement a warehouse based on the SAP Sybase IQ solution.

Monitoring the capacity of sections of the powered support

Building and configuration of infrastructure to collect data online from pressure sensors in sections of the powered support and preparation of reports and analyses to assess the operation of the powered support.

Launching ERP systems

Launch of a new system to support the management of enterprise resources (ERP) in Group companies. Business areas covered by implementations include in particular finance, accounting, HR and payroll, logistics.

Launch of a system to support project management

A platform has been launched and made available to support project management in accordance with the Methodology for Project and Program Management in the Group based on the Microsoft Enterprise Project Management environment.

Verification of the possibility of conducting the nanofiltration process in the conditions of supersaturation with calcium sulfate and its controlled crystallization

Analysis of the impact of nanofiltration parameters on the quality and cost of the obtained water and salt, and reduction of energy consumption in the installation through application of ultrafiltration, nanofiltration, reverse osmosis systems, evaporation method, crystallization and reduction of the quantity of obtained gypsum. The results of the composition of output water from the pilot installation will be used to calculate the energy consumption in the evaporation installation, the crystalizer, the amount of water and salt obtained. The results will also make it possible to reduce the quantity of waste in the salt production process. Based on, inter alia, this project, the Group seeks to achieve the circular economy objective.

Development of methods for production of innovative Certified Reference Materials (CRM) – new quality in the analytics of solid fuels

Project to develop methods for production of innovative products – matrix, certified reference materials (CRM) used in tests and analytics of solid fuels (hard coal). The product developed by conducting research and development will be the first product of this type made in Poland, with an additional set of unique properties, i.e. assigned (certified) values of five basic parameters; sulfur content (St), ash content (A), mercury content (Hgt) and metal #1 and metal #2.

Research and development to devise an innovative method for characterizing solid fuels

Development of an innovative method for characterizing solid fuels (coking coal). The conducted research and development work will allow for development of solutions introducing new quality in running technological processes from the perspective of ensuring appropriate coke parameters, safety of coke oven batteries and effective energy and overhaul management in industrial plants. As part of this project a classifier of hard coking coal grades and a methodology for measuring changes in the volume of the feedstock blend will be put in place.

Design of a system for identifying additives and mixtures in heating materials and the products of burning them

The project is executed in cooperation with the University of Silesia in Katowice under the Ministry of Science and Higher Education’s program “Implementation Doctorate”. The project aims to implement, in companies, new innovative methods identification of undesired additives in heating materials and the products of burning them using chemical and petrographic tests.

New structure of the shaft artificial bottom

The new structure of the artificial bottom of the shaft, with a mobile safety bridge enables dissipation of high kinetic energy of falling mass with a relatively small own mass. At the same time, the modular structure of the bottom allows for individual elements to be assembled on the surface, which reduces the costs and time needed for the assembly and disassembly of the artificial bottom.

Digital twin

Development of a system for comprehensive monitoring of the shaft infrastructure and diagnostics supporting tools, with the use of the state-of-the-art BIM creation technology and the Industrial Internet of Things. The effect of this work will enable us to determine the mutual flows between the individual elements of shaft building and furnishing, as well as to determine their impact on the correct operation of the entire shaft infrastructure, which in the longer term will contribute to cost reduction of shaft maintenance and equipment.

Individual means of transport

Design of a vehicle for self-transport over longer distances in underground pits.

Shaft partition

For Polish coal mining industry, a design of a shaft partition structure made from plastic is a pioneer solution. Low mass and convenient assembly method of partition elements will shorten the assembly time, which will have a positive impact on the financial aspect of the project.

Rescue conveyor

Making of a scraper conveyor for rescue-related activities, which will increase the efficiency of rescue worker teams.

Belt coveyor scales

Making of equipment for dynamic mass measurement, to be applied, among others, in belt conveyors. The compact and modular structure of the device allows it to be mounted both on new, as well as already operated conveyors.